For those that haven't seen this, here is what you get when you order an MFH kit. The 1/12 scale kit of the Abarth 1000 SP clocks in at 1.456 kg, relatively light by MFH standards -- the Alfa 8C 2900B kit (complete in the box) weighs 2.368 kg.

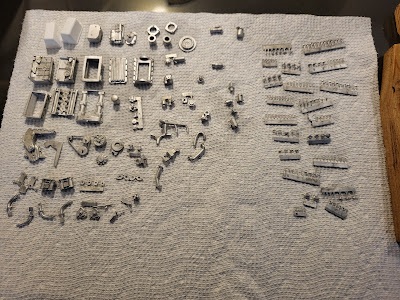

A large part of this is due to lots more resin, but there is still plenty of metal. Here's what it looks like when you open the box.

Here are the resin bits lined up.

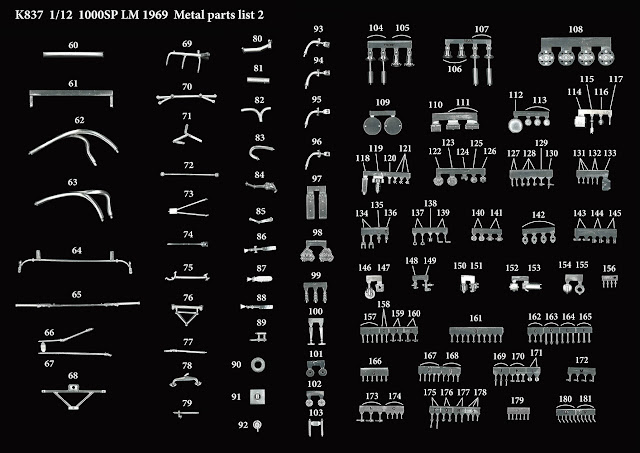

Six baggies full of metal bits are taped to a piece of cardboard in the bottom of the box. These all have numbers, but these are not stamped on the part or sprue; you have to take a guess at it or refer to the online guide as to what is what, as here:

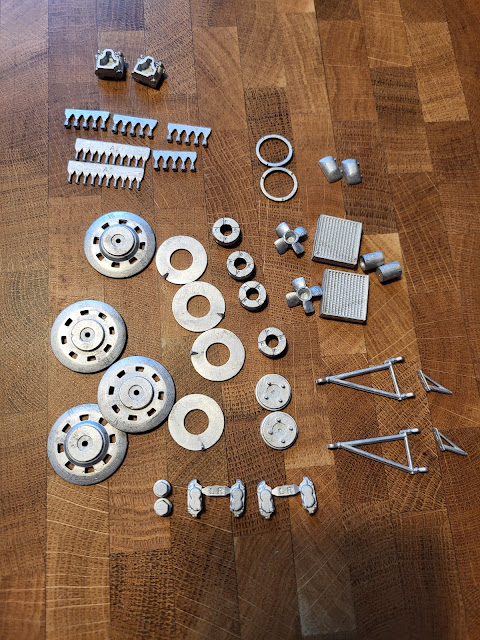

Bag #1 has wheel centre sections, radiators, brake discs and calipers and some assorted bits and bobs.

Bag #2 has some chassis bits, more parts of the brake calipers, inner door frames (the outers are resin), more chassis and suspension bits, and some unidentified doodads (UDDs).

Bag #3 has engine components, the major tubular section of the rear subframe, front floor pan section (the centre section is resin), steering wheel, the lid for the front access hatch (the only major external part made of metal), and more UDDs.

Bag #4 contains the belt drive for the engine, some suspension bits and some UDDs.

Bag #5 contains a lot of rivets and simulated bolt heads and assorted small bits.

Bag #6 (which I didn't photograph) contained more UDDs. Here it all is parted out into a small parts bin, more or less by category.

I'll document the construction carefully as I go through it, and hopefully won't wind up shelving it in frustration; this is not totally improbable as there are currently 3 other MFH kits either underway or on the Shelf of Doom, and a further 11 (mostly 1/24) not started. Now I just need to clear the decks, meaning finishing up the Alfa TZ2 which is almost done. Stay tuned!